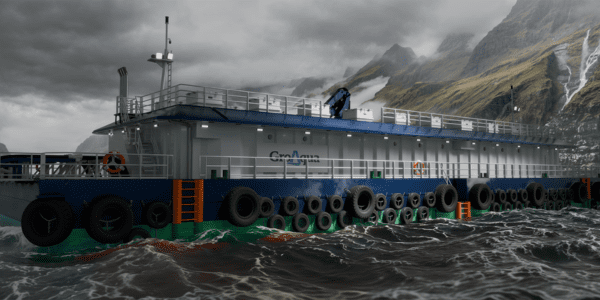

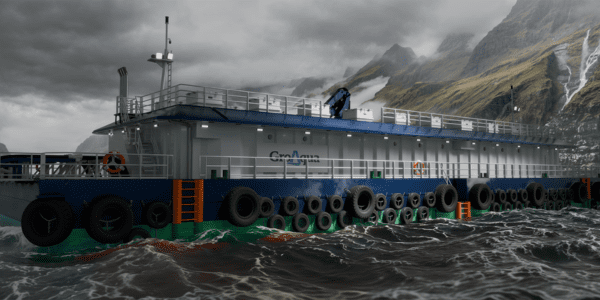

GroAqua Barge

The Ultimate Turn-Key Solution for Efficient Fish Feeding on Exposed Sites

Designed for remote operation and tailored to your needs, GroAqua Barge combines robust engineer with our advanced FishFeeder system, handling up to 24 feed lines and 1,100 tonnes of feed.

Product Range

Designed for remote operation and tailored to your needs, GroAqua Barge combines robust engineer with our advanced FishFeeder system, handling up to 24 feed lines and 1,100 tonnes of feed.

GroAqua Barge FF 480

– Front Feeding

– Aft engine room

– Remotely Operated

– Up to 480t of feed capacity

– Up to 8 feedlines

– 8 silos

– HS 5.5m

Options

– Bow Construction

– Lumpfish feed system

– Ensilage System

– Hybrid Power

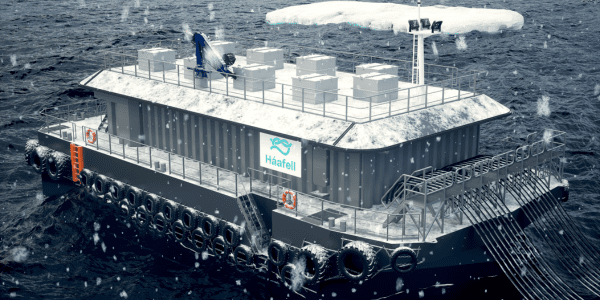

– Ice Class

GroAqua Barge SF 700

– Side Feeding

– Mid engine room

– Remotely Operated

– Up to 700t of feed capacity

– Up to 16 feedlines

– 12 Silos

– HS 5.5m

GroAqua Barge FF 700

– Front Feeding

– Aft engine room

– Remotely Operated

– Up to 700t of feed capacity

– Up to 18 feedlines

– 12 silos

– HS 5.5m

Options

– Bow Construction

– Ensilage System

– Hybrid Power

GroAqua Barge MF 700

– Front & Aft Feeding

– Aft engine room

– Remotely Operated

– Up to 1,100t of feed capacity

– Up to 24 feedlines

– 12 silos

– HS 5.5m

Options

– Bow Construction

– Ensilage System

GroAqua Barge FF 1000

– Front Feeding

– Aft engine room

– Remotely Operated

– Up to 1,000t of feed capacity

– Up to 16 feedlines

– 14 silos

– HS 5.5m

Options

– Bow Construction

– Ensilage System

– Hybrid Power

GroAqua Barge MF 1100

– Front & Aft Feeding

– Aft engine room

– Remotely Operated

– Up to 1,100t of feed capacity

– Up to 24 feedlines

– 18 silos

– HS 5.5m

Options

– Bow Construction

– Ensilage System

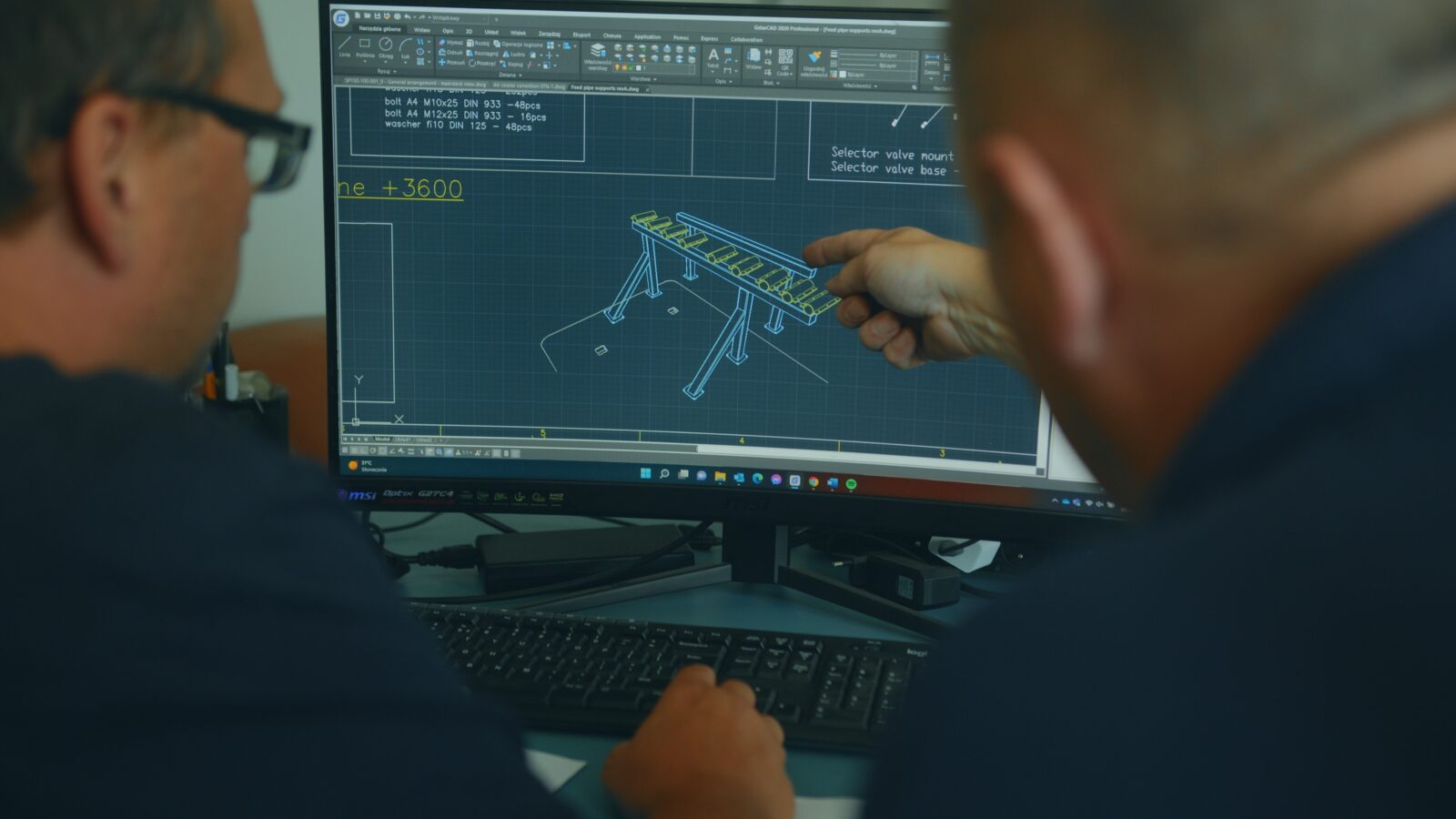

Built with Care and Attention to Detail

The GroBarge is built from the bottom up with care and attention to detail. Each barge is custom made to meet the specific needs of the fish farm it will be servicing. This ensures that the barge is optimized for the environment and conditions it will be operating in. Additionally, the barge is constructed using high-quality materials and components, which are designed to withstand the harsh weather and marine conditions of the North Atlantic.

The construction process of the GroBarge is highly controlled and monitored to ensure that every detail is executed to the highest standards. This includes the use of advanced welding techniques, strict quality control measures, and rigorous testing procedures. The result is a barge that is not only highly functional but also durable and reliable, providing long-lasting service to the fish farm.

We are here to

guide you

Do you have questions, speculations or want to

chat about possibilities, get in touch.

Kristian Andreasen

Head of Barge Sales

Robbie Duncanson

Sales (UK & Ireland)

Rúni Petersen

Head of Sales (Faroe Islands & Iceland)

Stig A. Benjaminsen

Head of Sales (Norway)

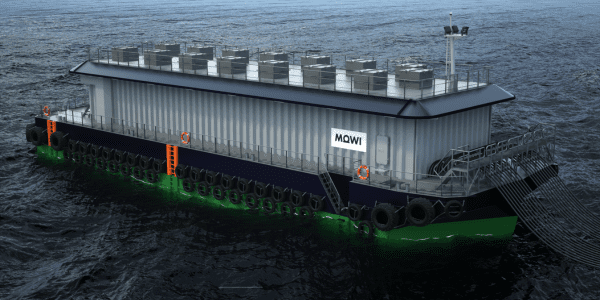

Qualities

The GroAqua Barge is designed specifically for fish feeding, with no wasted space or cost compared to prior barges. Its double hull design allows it to withstand some of the harshest weather conditions in the world. The barge also has a high feed silo capacity, which reduces downtime and increases overall efficiency. Additionally, its built-in FishFeeder fish feeding system eliminates the need for separate feeding equipment. The GroAqua Barge is also unmanned and remotely operated through the FishFeeder software.

The double hull design of GroAqua Barge provides exceptional stability, making it highly resistant to the heavy waves and rough seas of the North Atlantic. This is just one of the measures taken to ensure that the barge can withstand the harsh weather conditions of the North Atlantic, allowing fish feeding operations to continue safely and efficiently at all times.

Another quality of the GroAqua Barge is its high feed silo capacity. With a capacity of up to 1100 tonnes of feed, the barge is able to supply a large number of fish farming cages with food for extended periods of time. This feature also means that the barge requires less frequent refilling, which reduces downtime and increases overall efficiency.

With the FishFeeder fish feeding system already integrated into the barge, there is no need for separate feeding equipment, which can save time and money. Additionally, the built-in system can be customized to meet the specific needs of the fish farm, which can lead to more efficient and effective feeding practices.

One of the key features of GroAqua Barge is its ability to be unmanned and remotely operated through the GroVision software. This feature enhances safety by eliminating the need for onboard personnel. Additionally, it enables more efficient and cost-effective operations, as the barge can be controlled from shore. The GroVision software provides real-time monitoring and control of both the GroAqua Barge and the FishFeeder feeding system, which can be adjusted as necessary to meet the needs of the fish farm.

GroAqua Barge is engineered to thrive in any environment, from calm fjords to the harshest, exposed sites. Designed with robust construction and certified for significant wave heights up to Hs 6.5, our barges ensure reliable operation and safety, no matter the location. Custom designs are available to perfectly match your site conditions and operational needs.

Efficient dead fish management is critical for both environmental sustainability and operational value. GroBarge comes equipped with advanced ensilage systems tailored to your specific needs, ensuring stable and high-quality processing. With GroAqua’s proven solutions, you can maximize the value of byproducts while maintaining optimal hygiene and safety.

Reduce emissions, fuel consumption, and noise while extending equipment lifespan with GroAqua Barge’s cutting-edge hybrid power systems. By integrating battery storage with smart Energy Management Systems (EMS), our barges lower diesel dependency by up to 60%, offering a greener and more cost-effective feeding solution. Compatible with shore power and renewable energy sources, GroAqua Barge helps you meet environmental goals without compromise.

GroAqua Barge is designed with crew safety as a priority, offering watertight compartments, automatic bilge pump systems, fire alarms, and emergency exits. Safety ladders, non-slip flooring, and robust construction create a secure and efficient working environment, ensuring compliance with the highest HSE standards for aquaculture operations.

GroAqua Barge is built to meet or exceed all applicable industry regulations, including NS 9415, NYTEK, and NEK 400 standards for aquaculture facilities. Whether operating in Norway or internationally, our barges are certified for compliance with safety, structural, and electrical requirements, giving you peace of mind and reliable performance wherever your operations take you.

Gallery